History

One billion burs later

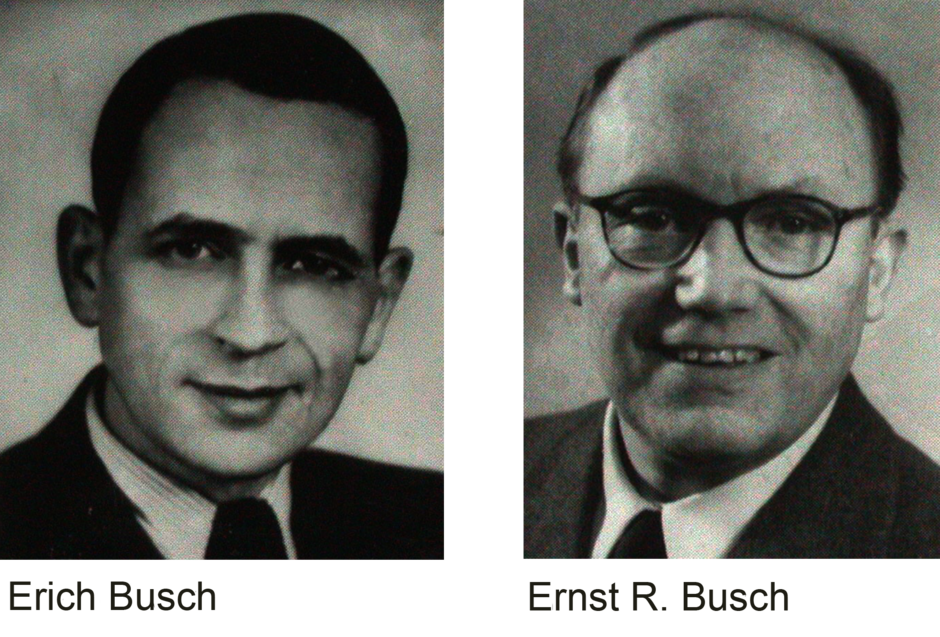

When the brothers Ernst and Otto Busch set up their dental bur factory Busch & Co. in Düsseldorf in 1905, they probably never expected that its productivity would be described with these words just 100 years later!

Their intention was to give a further boost to the still fledgling field of dentistry (there were 500 dentists in the whole of Germany in 1905) by producing better instruments. They and the two following BUSCH generations succeeded admirably, in this respect, as the company's entire history after moving to Engelskirchen in 1908 is characterised by its constant adjustments to the latest developments in science and technology.

New product series e.g.:

- ceramic-bonded abrasives

- the first dental carbide burs in Germany

- diamond-coated grinding instruments

became the milestones of its further development.

The elementary innovation steps based on novel types of cutting materials boosted thousands of new products which – from an objective point of view – gradually contributed to lowering the fear of a visit to the dentist.

The acquired know-how was, moreover, used to the benefit of other users who soon came to appreciate the high-quality of BUSCH’s dental products. In particular the goldsmiths, jewellers and podologists became true supporters and inspired the numerous innovations of Busch & Co. which are the premium products manufactured with high-tech today in Engelskirchen and delivered to almost 100 countries around the world.

Acquisition of a decommissioned ironworks in Engelskirchen

Apropos Engelskirchen: it was probably the “genius loci” that enticed the two brothers into the valley of the Agger river – but maybe it was the hydroelectric power station in the former ironworks the company acquired, or perhaps even the wealthy brother-in-law in the neighbouring village of Ründeroth, who initially helped to finance the project - yet not only the local people and town of Engelskirchen profited from the corporate purpose of this new factory, which was at that time one of a few.

While Busch & Co. provided jobs for up to 180 people, former employees who had learned their trade at Busch started out to set up their own businesses and provided jobs for another 1000 people. These firms were not only dental bur manufacturers, but also related branches manufacturing cutting and grinding tools as well as twist drills. One former employee even established an injection-moulding firm that rose like a phoenix from the ashes and took on orders from Busch.

This extraordinary boom in Engelskirchen ended with the 2nd World War.

Many of the firms still exist today, however, and have provided a sound basis to the local industry up to the present.

The second BUSCH generation

had to cope with the impacts of the 2nd World War, such as a shortage of materials and dismantlement; on the other hand, it succeeded early on in producing dental carbide burs as the first dental firm in Germany.

This was a prerequisite to provide dentistry with adequate instruments that were designed to withstand the load of high-speed drives. That was a true pioneer achievement with influence until today and into the future.

Without going into details of the countless innovative products, it was the preserve of

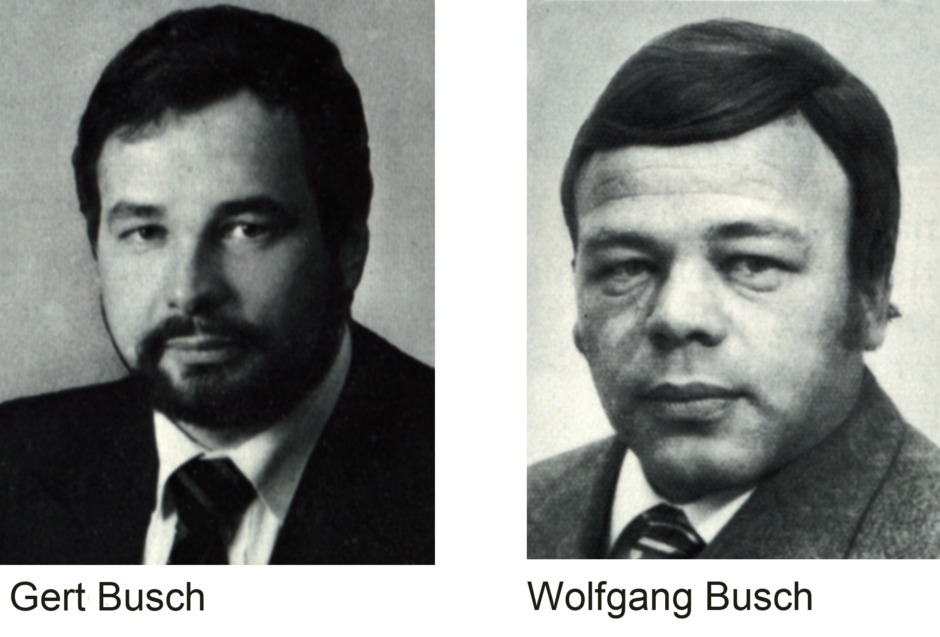

The third BUSCH generation

to develop and expand the manufacture of diamond-coated instruments using state-of-the-art technology.

This basis ensured that a broad range of customers, beyond the borders of the dental market, could be provided with a complete series of premium instruments.

Past and present show that in this company, managed today by Gert Busch, business decisions are always oriented towards the benefit of the end-user.

Not least, this also includes the promotion of long-term external projects. For example, BUSCH supports aid organizations such as e.g. Deutsche Welthungerhilfe /German Agro Action, Deutsche Krebshilfe /German Cancer Aid, the voluntary fire brigade in Engelskirchen, the Cologne Rundschau Geriatric Care Organization and numerous other aid organizations.

Source: miscellaneous press releases